What we can do for boundless growth

We maintain a manufacturing mindset focused on meeting customers’ needs in terms of quality and price, while also actively contributing to the achievement of Sustainable Development Goals by maximizing our efforts and contributions.

Company-wide initiatives

- Attaining a decarbonized and recycling-centric society

-

- Our company vehicles are replaced with low-pollution, energy-saving models during renewals.

- Creating a diverse and healthy work environment for all employees to thrive

-

- By digitizing pay slips, purchase slips, and internal application documents and transitioning from physical papers to an internet-based system, we can not only save valuable resources but also significantly enhance the efficiency of our operations.

- We’ve set up designated smoking zones across all workplaces to prevent second-hand smoke exposure. Additionally, we’ve assigned specific days as non-smoking days to organize activities aimed at promoting smoking cessation for both smokers and non-smokers.

- Creating a work environment that attracts and retains employees, where individuals not only excel in their own department but also actively participate in cross-departmental learning sessions, fostering collaboration and knowledge-sharing throughout the entire organization.

- We actively promote the recruitment of individuals with disabilities by collaborating with schools and organizations serving disabled individuals. We also conduct training sessions to support their professional development.

- We provide a supportive system for employees with children, in accordance with equal employment opportunity laws. Our hourly time-off system allows individuals to take short breaks to attend to personal errands and family needs.

- We are committed to establishing systems that adhere to the principle of equal pay for equal work.

- Related SDGs

Activities at manufacturing sites

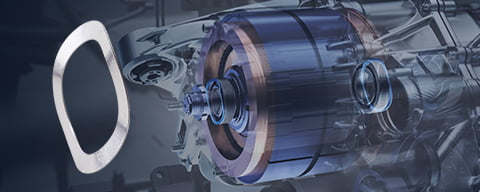

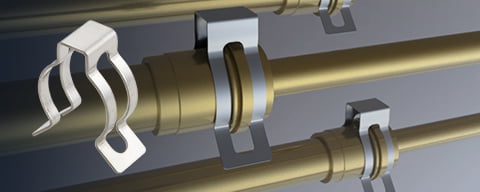

- Delivering products and services of superior quality and safety

-

- We are proactive in preventing the introduction of materials containing banned substances by diligently obtaining safety data sheets. We ensure that no substances prohibited by RoHS regulations are present in subsidiary materials and chemicals used across our manufacturing sites.

- We send employees from our manufacturing sites in Indonesia and Vietnam to Japan for training, where they gain valuable knowledge in techniques, know-how, and language skills.

- Reducing environmental impacts of our business

-

- When designing new products, our design engineering team prioritizes minimizing raw material waste and incorporates recyclable design elements as necessary, demonstrating our commitment to waste reduction.

- We ensure that generated wastes are properly segregated and managed in accordance with the Waste Management and Public Cleansing Act. Our waste disposal is entrusted to certified industrial waste management companies authorized by the relevant authorities for proper processing.

- We are actively upgrading our factory equipment by replacing all compressors with high-efficiency models and switching lights to LED lights fixtures, demonstrating our commitment to energy conservation and efficiency.

- Related SDGs

Other activities

- Reducing environmental impacts of our business

-

- Our factory’s drainage system adheres to municipal government standards, which are often more stringent than national regulations. We maintain stringent management of our drainage system to ensure the long-term safe usage of water.

- By transitioning from wooden pallets to plastic pallets at our manufacturing sites, we not only reduce the need for wood consumption but also benefit from the enhanced durability of plastic pallets, leading to reduced waste generation.

- Related SDGs